P-Life Japan Inc. develops practical solutions for plastic waste reduction. The Japanese company, established by Isao Toyama as CEO, advances biodegradable technology to improve plastic manufacturing methods for environmental sustainability by removing microplastics. Claudio Fernandez, spokesperson for P-Life Japan Inc., describes the company’s technical developments and ecological effects.

Traditional Plastics Threaten Human Health and Ecosystems

Plastics have served as a foundation of modern life, yet their environmental impact demands attention. Traditional plastics, made from non-biodegradable materials like polyethylene and polypropylene, add heavily to pollution. They persist for centuries before decomposition, creating a legacy of waste that harms ecosystems and wildlife. The effects of plastics on human health have become clearer.

Scientists have discovered microplastics in lung specimens of patients with cancer and chronic lung disease, highlighting the risks of plastic exposure. Workers exposed to plastic fibers experience lung problems and reduced lung capacity, possibly due to inflammation caused by these particles.

P-Life’s Patented Biodegradation Breakthrough

“The health implications of plastic exposure require urgent action. Our mission aims to reduce plastic waste while creating products that protect human health and the environment,” noted Claudio Fernandez, spokesperson for P-Life Japan Inc. P-Life Japan Inc.’s biodegradable technology provides a viable solution through accelerated and safe plastic degradation.

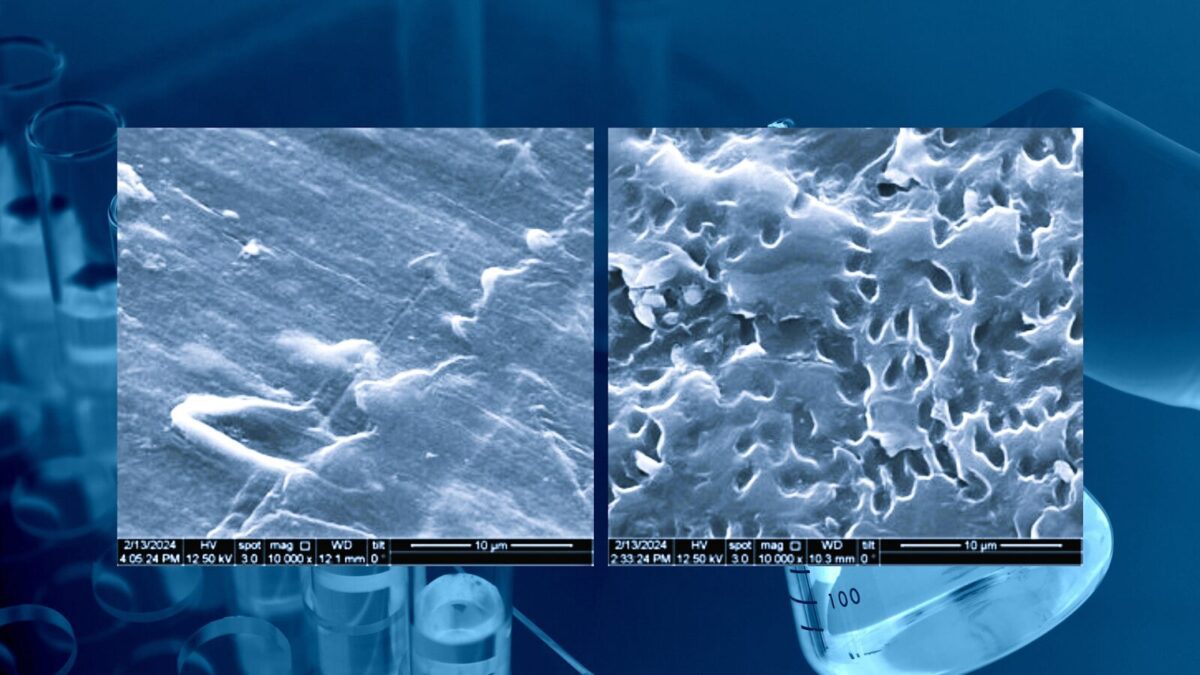

Its technology incorporates a proprietary additive into polyolefin polymers, allowing these plastics to break down into smaller compounds for microbial consumption. This process is based on the catalytic reaction of oxidation and reduction by our specially formulated additives. It transforms non-degradable plastic polymers into lower molecular weighted substances with multi-functional groups so that microorganisms can assimilate them finally.

P-Life Japan Inc. worked with researchers from Keio University on a groundbreaking project. The team discovered a suitable biodegrading bacterium for polypropylene (PP) using the biodegradation-promoting additive P-Life. This discovery, led by Professor Kenji Miyamoto of Keio University, offers new possibilities for microbial biodegradation efforts, particularly with polyolefins — degrading bacteria that can be expected to be effective in decomposing and removing microplastics produced from polyolefin-based plastics and eliminating their accumulation in the global environment.

“Our technology enables manufacturers to adjust the lifespan of their plastic products. Packaging for single-use items degrades in months, while more durable products like shampoo bottles maintain their performance longer,” Claudio Fernandez explained. This adaptability makes P-Life’s technology valuable to companies that want to improve their sustainable profiles.

The Business Case for Biodegradable Plastics

The company’s technology creates advantages beyond environmental benefits. It offers economic value through biodegradable plastic production without major infrastructure changes. Companies can transition to sustainable practices while maintaining costs and product quality.

“The cost of integrating P-Life into manufacturing processes remains minimal, typically requiring only a small percentage of the additive. This creates an appealing option for businesses reducing their environmental footprint while protecting their bottom line,” Claudio Fernandez shared. The work with Keio University strengthens P-Life Japan Inc.’s progress in biodegradation technology, establishing it as a leader in sustainable plastic industry advancement.

P-Life’s technology meets various international standards, including ASTM, ISO, JIS, FDA, and RoHS. The SP Technical Research Institute of Sweden conducted tests that proved P-Life fulfills all requirements of SPCR 141 Appendix 4, following ASTM D6954. P-Life passed Tier 1, 2, and 3 testing, demonstrating 91% biodegradation within 24 months in soil.

Its technology supports a circular economy through multiple plastic recycling cycles without property loss. This aligns with worldwide efforts to reduce waste and boost recycling rates, making P-Life a crucial player in the sustainable plastic industry transition.

P-Life’s Global Mission for Plastic-Free Oceans

P-Life Japan Inc. will shape the plastic industry’s future. The company tackles current environmental challenges through advanced technology and sustainable practices. The world is moving toward sustainable methods, and P-Life Japan Inc.’s biodegradable plastics will become essential to industry transformation, creating a future where plastics serve a function and environmental responsibility.

Its influence will spread globally through increased adoption of its biodegradable technology. “We want sustainable plastics to become standard practice. Through partnerships with industries and researchers worldwide, we will build a future where plastics become part of the solution rather than pollution,” Claudio Fernandez emphasized. This outlook demonstrates P-Life’s drive to guide the plastic industry toward sustainability.

To enhance biodegradation capabilities, p-Life Japan Inc. maintains research partnerships with scientists and industries worldwide. This teamwork integrates current scientific discoveries into P-Life’s technology, reinforcing its position in sustainable plastics. Through ongoing research and development, P-Life tackles new challenges in the plastic industry, keeping its technology at the forefront of sustainability.